Capacity testing is an operation to accurately determine the capacity Q [Ah] of the DUTs, meaning precision measurement. This process normally takes a long time.

There are several methods of capacity testing, but the most accurate is the following process.

-

Disassemble the battery pack into modules.

-

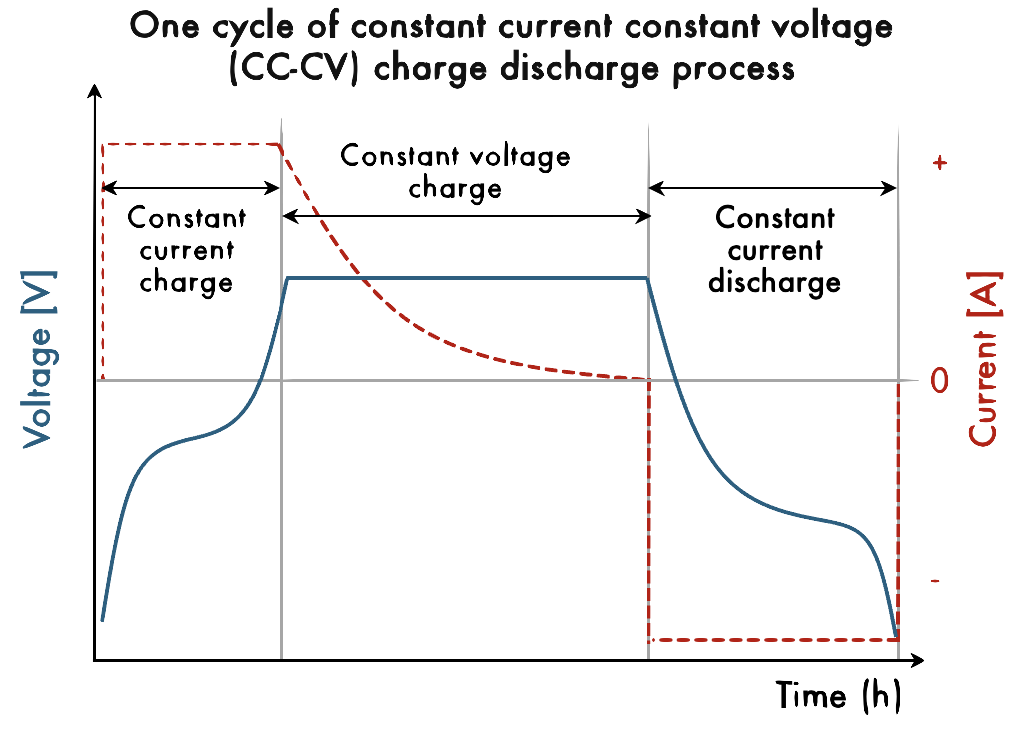

Fully charge the battery Q and discharge at a constant current I [A].

-

The time t [h] is measured until the discharge is completed, then Q = It [Ah

-

Normally 20 to 24 hours, and 3 days when the DUT is left to stand overnight and measure again. Accuracy depends on the measurement time.

-

In addition, load tests are carried out under actual in-vehicle conditions before shipment in many cases.